ABOUT LWDED

LWDED is dedicated to revolutionizing learning and workforce development through innovative solutions, empowering individuals and organizations to achieve their full potential.

ADDere is a division of Midwest Engineered Systems, a manufacturing company with a speciality in attempting unusual projects. The company, which began in 1991, now operates some 4,000 making machines worldwide and offers a variety of manufacturing services to industry. One of the more recent additions to their services is additive manufacturing. However, unlike many service providers who simply choose a 3D printer system from a vendor and operate it, Midwest Engineered Systems in 2017 decided to build their own 3D printer. They believed the existing options to be too expensive, too small and too slow to fit with their customer base. Midwest Engineering Services created a new division called “ADDere” to handle the development and operation of this technology.

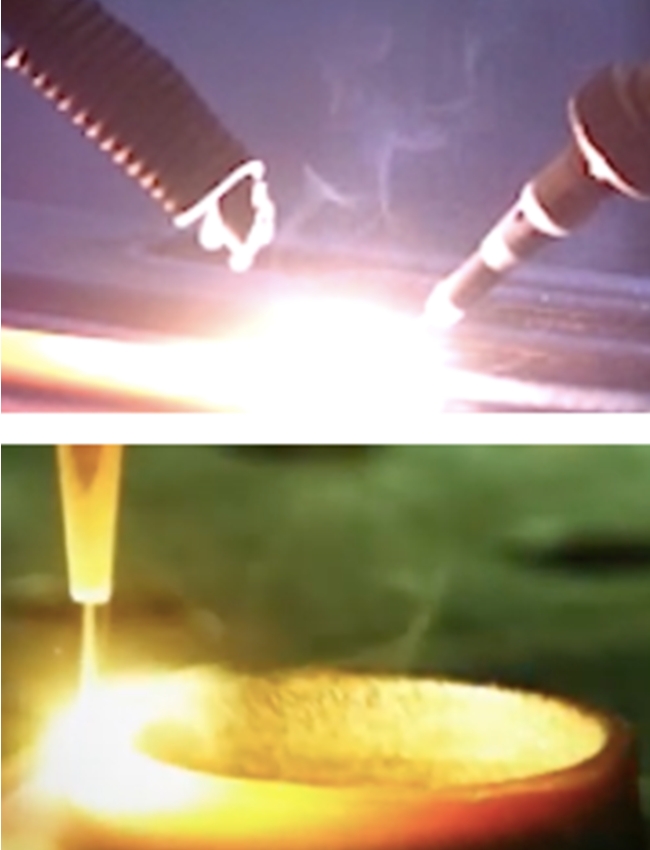

Laser-Wire additive manufacturing (LWAM) is a technology in which 3D components are built by continuously feeding a wire into a melt pool generated by a laser beam. Fully dense components can be produced at high deposition rate. Wire-feed additive manufacturing is efficient and cost-competitive in producing large expensive metal components with complex geometry in many industries especially for aerospace and automotive industries.

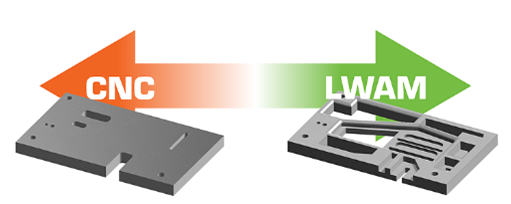

For the parts that are more solid than complex, CNC machining is the direction to go. Starting from solid billet and carving features becomes more economical than waiting for the laser powder process to slowly build the thicker material. CNC production can also go well beyond the scales offered with typical SLS machines.

The same criteria that makes CNC machining the champion over SLS, is where Laser Wire Additive Manufacturing (LWAM) begins to make more sense. More specifically, when a large metal part is needed that’s too large and high mass for SLS but would also require a substantial amount of time removing material on a CNC mill, LWAM is the direction to investigate.

What LWAM can do is essentially 3D print a metal component at a casting grade of finish. Going with this process first can reduce CNC machining sometimes by more than 80%, while saving waste material costs in the process. With LWAM, almost 97% of the material used in the process goes into the part. Where LWAM is not a good fit is where parts are small in scale and are extremely Complex.

ABOUT LWDED

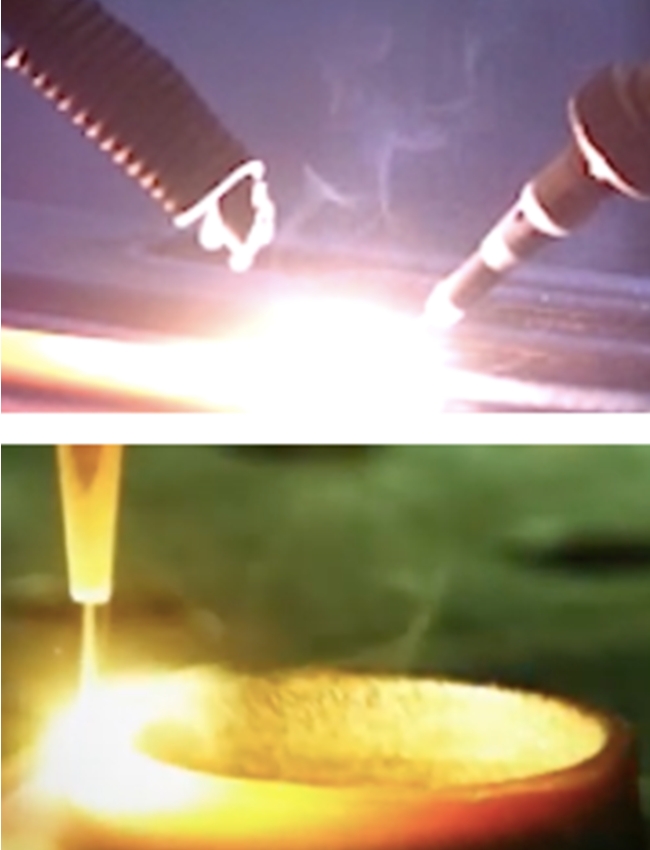

Further down-selecting within the laser wire DED additive manufacturing field, there are two fundamental alternatives: off-axis wire feeding and coaxial wire feeding. Off-axis, wire-fed laser additive manufacturing can be accomplished with a simple combination of a wire feeder and laser focusing optics. Off-axis wire feeding requires that the wire-feeding mechanism be rotated as the build process changes direction on the part. This “last axis” complexity (also shared by GMAW additive manufacturing) can constrain process motion and add to part path motion complexity

So, to eliminate this complexity/constraint, a number of research organizations and laser equipment manufacturers have introduced coaxial wire feeding solutions. While each of these “coax” solutions delivers wire perpendicular to the work surface and offers omnidirectional motion, several of the laser beam delivery solutions actually use multiple, distinct, and adjustable focal spots to melt the wire.

ADVANTAGE

The advantage of this Wire based deposition process is the low material loss (<2%), faster build rate, and low cost of materials. As you know, the cost of metal powder for use in 3D printers can be quite expensive due to the process required to manufacture it. However, the Wire based system uses only standard metal wire that is commercially available everywhere, which can be as much as half the price of powder.

ABOUT LWDED

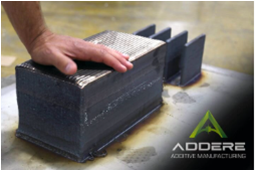

Because of high deposition rate the technology is ideal for creating larger objects, such as those that are likely to be used in aircraft engines, air frame structures or other large mechanical systems for aerospace, defense & marine industry. As an example, you can see this 55kg block of titanium, which was 3D printed in only six hours!. It seems, that ADDere’s system can already 3D print 240kg per day.

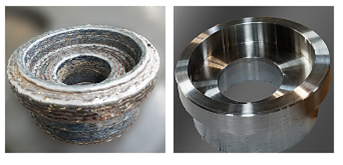

The disadvantage of this technology is that it cannot generate fine feature parts that is possible with Powder based DED technology. Also, as the surface roughness of the part is higher as compared to other technologies, it sometimes requires finish machining work.

ABOUT LWDED

Further down-selecting within the laser wire DED additive manufacturing field, there are two fundamental alternatives: off-axis wire feeding and coaxial wire feeding. Off-axis, wire-fed laser additive manufacturing can be accomplished with a simple combination of a wire feeder and laser focusing optics. Off-axis wire feeding requires that the wire-feeding mechanism be rotated as the build process changes direction on the part. This “last axis” complexity (also shared by GMAW additive manufacturing) can constrain process motion and add to part path motion complexity

So, to eliminate this complexity/constraint, a number of research organizations and laser equipment manufacturers have introduced coaxial wire feeding solutions. While each of these “coax” solutions delivers wire perpendicular to the work surface and offers omnidirectional motion, several of the laser beam delivery solutions actually use multiple, distinct, and adjustable focal spots to melt the wire.

APPLICATION

Printing parts with the laser-wire additive system produces a large component quickly, that’s ready for finish machining. The system also reduces waste material costs associated with other methods available – sometimes using up to 99% of the material on the product!

Industrial

Here is an example of Mold Forms for Rubber Parts. It took 3 hour build time with 3D laser-wire additive process thereby reducing expensive subtractive processes. Carbon Steel metal printing process allowed customer to move into production faster and more cost effectively than conventional processes. Deposition rate: 6 Lbs./h Build time: 3 hrs. Equipment used: ADDere I System

Marine

Here is an another example of boat propeller. Thin-walled metal baldes were 3D printed onto existing part and post-prcessed for finish later. Deposition rate: 3 Lbs./h Build time: 4 hrs. Equipment used: ADDere I System

Aerospace

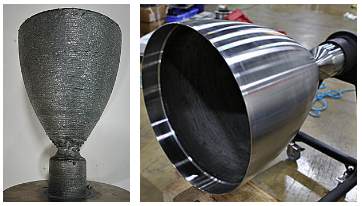

Unique capability of printing an entire rocket combustion chamber and rocket nozzle as one seamless rocket thrust chamber assembly completely from stainless steel. Producing these components as one seamless part reduces the total part count of the thrust chamber and the chances for a catastrophic failure.

Rocket Thrust Chamber Assembly

Seamless SS part that stands 42in tall with a wall thickness of 3mm.

Deposition rate: 4 Lbs./h

Built time: 20 hours

Equipment used: ADDere III System