FEATURES OF ADDERE SYSTEMS

Addere Systems offers cutting-edge technology solutions designed to streamline operations, enhance efficiency, and drive innovation across industries

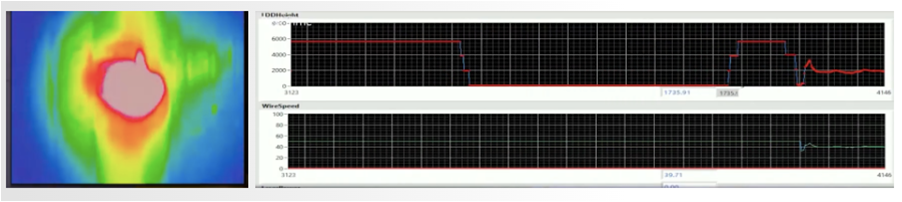

ADDere Real-Time Sensor System

During any additive manufacturing process, the 3D printed build quality is highly dependent on accurately maintaining dimensional and process parameters during metal deposition. Location, size, temperature, material quantity and machine speed are just some of the characteristics that need to be maintained for a quality 3D printed par

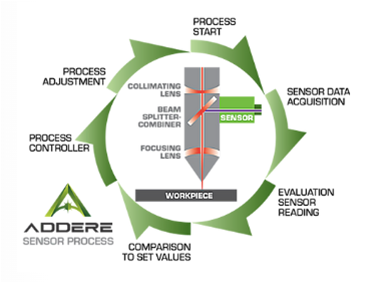

Integrated DSCS (Dynamic Sensor Control System)

Dynamic real-time surface profiling control Maintain print height throughout build Maintain working z-offset position Wire feed speed control Maintain weld pool characteristics

Closed loop, real time sensor feedback

Dimensional sensor to maintain meltpool size Thermal sensor to monitor and maintain part temperature chracteristics ADDere’s Wire Additive Laser Software (WALS) is a comprehensive closed-loop software and sensor machine control package that takes the directed energy deposition process to the next level of quality and consistency by monitoring and reacting to these inputs in real time.

WALS Control System Advantages

WALS closed loop system takes complete advantage of the configurability and pliability of the ADDere LWAM system The dynamic adjustment by WALS ensures consistent 3D printed build quality and near-net shape metal part production WALS controls heat and material deposition inputs to minimize distortion, porosity and impurities Each 3D printed layer is recorded for both sensory feedback and system adjustments to ensure a consistent build in current and successive parts.

WALS allows the user to predefine values during the initial planning phase, as well as allowing for adjustments during the actual 3D printing build phase. The WALS algorithms adjusts robot speed, laser power, wire feed speed and wire preheating to ensure the correct geometry is being created

O2 Purification System Option

O2 purification system includes monitoring sensor, necessary filters and automatic regeneration system which allows to reach oxygen & moisture concentration < 20ppm H2O. The system also includes a vacuum pump for regeneration, pressure control and evacuation

Floor Space ADDere system is built with shop floor space efficiency in mind. All of the laser wire additive system's components are built on a portable frame allowing the system to be easily relocated. Laser deposition robot and part positioner mounted on the main equipment base. A second base is designed to house the required auxiliary equipment such as the laser power, chiller, air handling unit, computer systems, and electrical control panel. The two bases are designed to be mounted adjacent to one another to minimize the overall footprint and provide ease of access for operation and maintenance.