About WAAM.

WAAM (Wire Arc Additive Manufacturing) revolutionizes 3D printing with advanced metal deposition technology, enabling efficient, large-scale production. It combines precision and sustainability for industries seeking innovative manufacturing solutions.

WIRE ARC ADDITIVE MANUFACTURING

WAAM SYSTEM . The technology of Robotic Wire Arc Additive Manufacturing (WAAM) is essentially a welding robot programmed such that it deposits metal material layer-by-layer repeatedly to create specific metal applications

HARDWARE SETUP SYSTEM

Robotic WAAM builds parts layer-by-layer by melting and dispositioning metal wire into the desired near-net-shape precisely. Open articulated robot systems are the most flexible and can be modified to fit each application’s specific needs. Enclosed Cartesian systems offer the highest positional accuracy and process control. Tool attachments can transform existing equipment into a hybrid, additive, and subtractive system.

CONTROL SYSTEMS

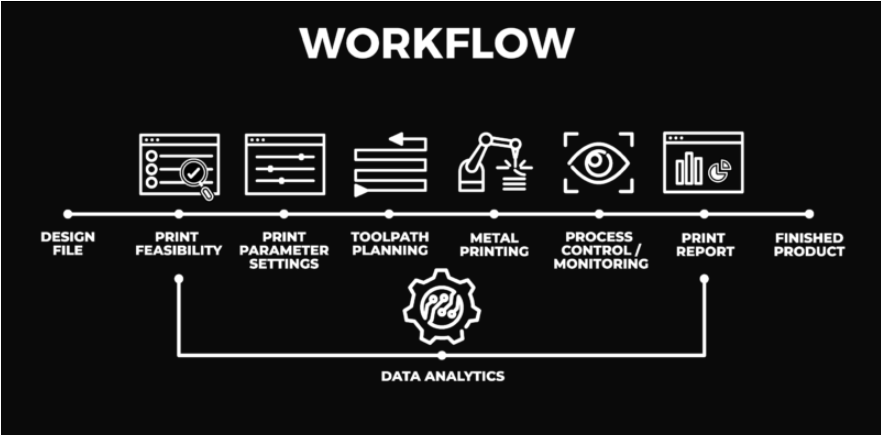

The software that controls the WAAM System dictates all process operations and ensures that the part is manufactured as intended. It includes: Tool path generation to convert designs in to machine instructions and printing strategies. Robot kinematics control to transform all programming into physical motions. Sensors for safe and efficient operations to ensure high quality prints.

ROBOTIC WAAM