Applications Notes / Bulletins

Browse IR Fiber Laser Technical Bulletins

In metal cutting, for example, a small beam with relatively high beam quality provides the highest speed for thin material, but the maximum thickness is limited by the resultant narrow kerf, which impedes ejection of the melt. A larger and more divergent beam (lower beam quality) allows cutting of thicker plate, with a corresponding speed penalty for thin sheet. A metal cutting tool with a small beam will thus be unable to cut thick plate, whereas a tool with a large beam will not be economical for cutting thin sheet.

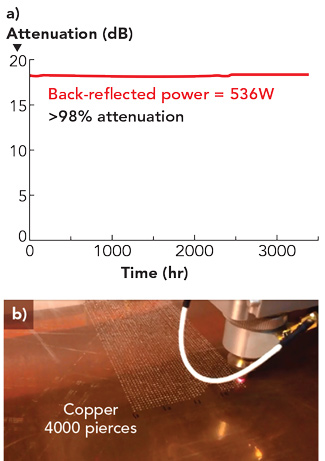

Furthermore, different beam shapes are optimum for different process steps. For instance, the piercing rate for thick metal can be increased significantly using a small beam, with the cutting speed or edge quality of the subsequent cut being optimized with a larger beam.

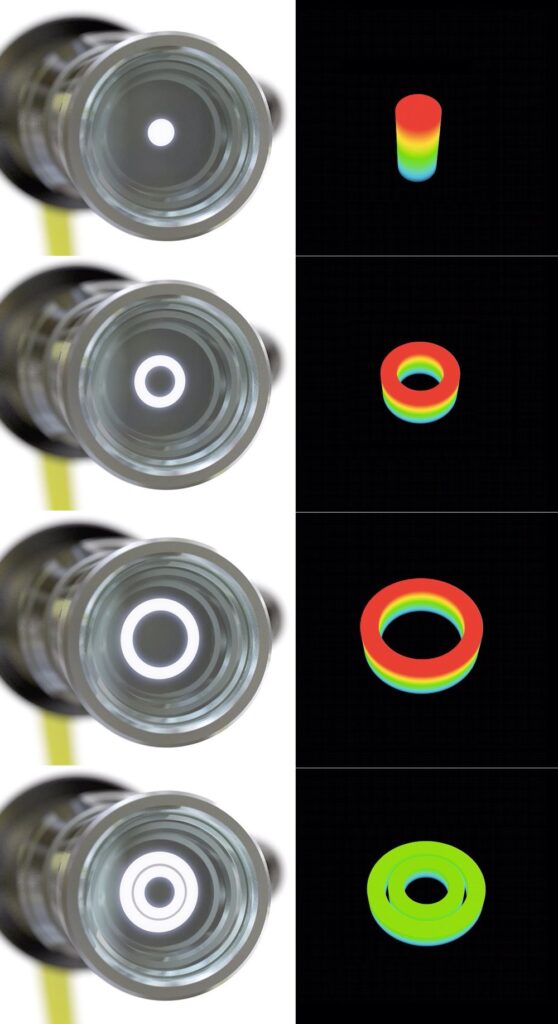

nLIGHT CoronaTM Fiber Laser provides rapidly tunable beam quality at multikilowatt power levels. These fiber lasers employ a novel, all-fiber technology to deliver a wide range of beam shapes and sizes directly from the laser output fiber. Several Corona-enabled metal cutting tools have been introduced by leading tool integrators

Keywords :

- Variable Beam Shape.

- Thick & thin sheet cutting.

- Material Processing.

- CoronaTM Fiber Laser.

Variable beam high power fiber laser with optimized beam characteristics for metal cutting

Industrial laser welding continues to experience rapid growth, driven by numerous performance and cost advantages over alternative welding technologies.

As laser welding makes inroads into existing products and enables new capabilities and applications for metal manufacturers, end markets are undergoing unprecedented change.

For decades, industrial lasers have provided fixed output beam characteristics. Attempting to optimize this fixed beam profile to each welding application was primarily restricted to adjusting the optical magnification of the process head. Although a few niche applications used beam-shaping optics to improve the laser welding process, such as a twin spot wedge for zinc vapor mitigation or an axicon for ring beam shapes in deposition processes, these traditional methods add cost and complexity to the process head and are not widely employed.

To avoid the drawbacks of free-space optical methods, the nLIGHT Corona fiber laser uses all-fiber technology to enable rapid tuning of the fiber laser beam size and shape directly from the feeding fiber. These fiber lasers provide a wide range of beam shapes and sizes and allow rapid, on-the-fly beam tuning without any loss of power, stability, or reliability.

Is beam shaping the future of laser welding?

In past few decades, fiber lasers have come to dominate laser-based industrial materials processing because they provide an unmatched combination of low cost of ownership, low per-part cost of production and high reliability. A key advantage of fiber lasers is reliability. They require no consumables other than electricity; require no optical alignment, routine maintenance or calibration; and exhibit extraordinarily long life when designed around the right high-performance components.

Even with fiber lasers’ unprecedented reliability, the need for service might occur. In this situation, rapid diagnosis and repair are critical to minimize loss of productivity and, therefore, any repair should be performed at the machine to minimize downtime. Unfortunately, there are some lasers that fall short of these critical requirements where the tool integrator is unable to repair or diagnose the source of the failure at user site, making the end user to remove the laser from the machine and transport it to the laser manufacturer’s service depot, thereby substantially decresing productivity and increasing downtime & costs.

Recognizing the importance of serviceability, nLight designed its next- generation fiber lasers to facilitate rapid, on-site service, if needed. Also, its flexible training program enables tool integrators to diagnose and repair the most common sources of failure.

Keywords :

- Simple & Easy Service.

- Rapid Field Service.

- Flexible Training Programs.

Maximizing uptime - How novel designs and flexible training enable world-class service.

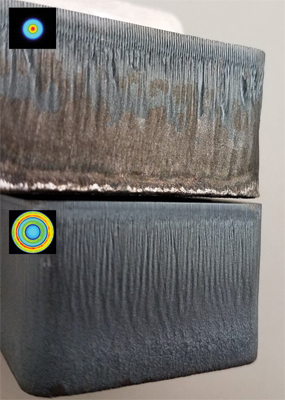

nLight has developed a novel, all-fiber technology, “Corona”, that enables rapid tuning of the fiber laser spot size directly from the feeding fiber over a range of more than 3× without any of the drawbacks of free-space approaches. In addition, Corona fiber lasers provide beam shapes that have shown improved cutting quality for various metals, including flat-top and annular (“donut”) beams. Corona fiber lasers at the 4 kW power level have delivered greatly improved perfor- mance over conventional fiber lasers for sheet metal cutting of mild steel, stainless steel, aluminum, and copper, for mild steel thicknesses up to 25 mm, enabling the development of “univer- sal” tools for optimized cutting of a wide range of metal thicknesses.

The general metal cutting market, including laser cutting, is dominated by thick mild steel (MS) plates. The Corona fiber laser offers unique benefits in edge quality and maximum thickness for thick MS cutting compared to other laser systems.

Keywords :

- Metal Cutting.

- Better Edge quality.

- High Cutting Speed.

- Variable Beam Shape.

A Breakthrough for Fiber Lasers - Tunable beam quality enables optimized cutting of thin and thick metal