Ultrafast Laser

Browse Ultrafast Laser Technical Bulletins

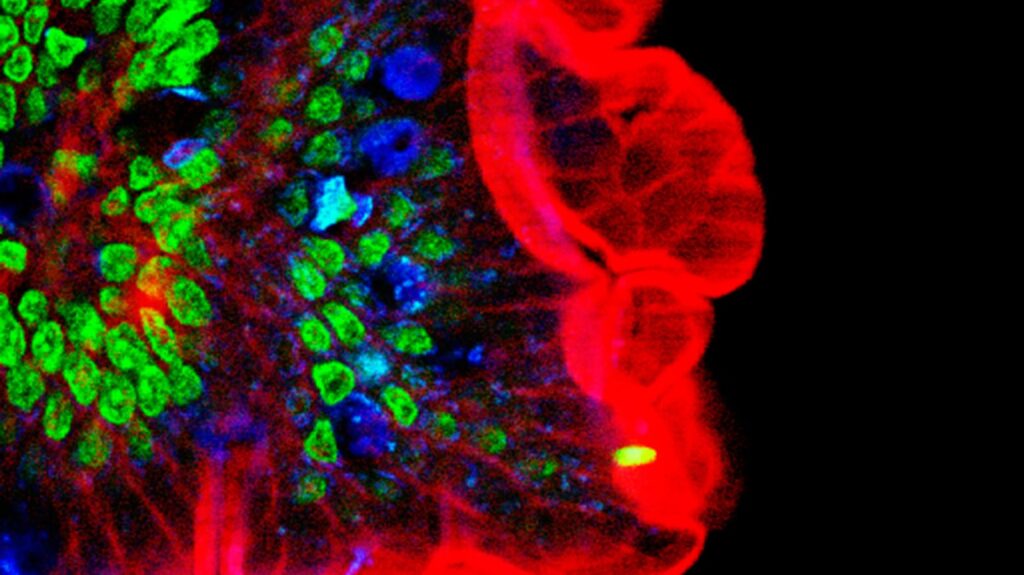

Two-photon microscopy provides deep-tissue imaging in thick/live samples. Efficient two-photon excitation requires ultrafast-pulsed lasers capable of producing high peak power with low pulse energy to avoid degradation of living cells. Higher wavelengths at 920 nm and in the 1030–1120 nm wavelength range are now preferred to reduce scattering and optical damage and to excite fluorescent proteins. Alcor 920 femtosecond fiber laser can produce <100 fs ultrashort pulses with up to 4 W average power at 920 or 1064 nm peak wavelengths with an 80 MHz pulse repetition rate

Keywords :

- Ultrafast Fiber Laser.

- Multiphoton Microsocpy.

- Deep Tissue Imaging.

Femtosecond fiber laser at 920 nm improves two-photon microscopy imaging.

In 2-Photon Microscopy, majority of fluorescent proteins of interest to biologists have a two-photon absorption band primarily in the 900 – 1100 nm range.

Whereas in optogenetics, laser sources at around one micron offer deeper penetration into cellular tissues allowing for excitation and activation of cells easing the understanding of neuronal subcellular activities.

Fiber laser technology is more suitable in the 900nm and 1 μm range offering much higher average power as well as higher peak power and pulse energy than traditional Ti:Sapphire lasers with all the benefits of fiber lasers.

Spark Lasers’ Alcor dual answers these challenges, providing femtosecond pulses at 920 and 1064 nm from two separate laser heads for optimal flexibility and ease of use..

Keywords :

- 2-Photon Microscopy.

- Opto-genetics.

- Neuroscience.

- Dual Laser at 920 & 1064nm.

Dual Wavelength Ultrafast Fiber Lasers for Multiphoton Microscopy & Opto-genetics.

Laser Micromachining is well established in industry. Ultrafast laser machining using pulses with pico or femtosecond duration pulses is gaining traction, as it offers very precise processing of materials with low thermal impact.

Ablation by ultrafast lasers results from a series of complex nonlinear phenomena of absorption and transfer of energy that take place in the surfaces of materials upon irradiation. Provided that a good window of processing parameters is chosen, the resulting thermal effects are in general negligible, making ultrafast lasers excellent micromachining tools applicable to most types of materials.

This is because longer pulse (nanosecond) and continuous-wave (CW) lasers have a photothermal interaction with materials, creating a heat affected zone (HAZ) which limits the minimum size of features that can be cleanly machined. It can also cause functional and structural problems, e.g., damage to underlying semiconductor circuitry, or microcracking that weakens glass touchscreens. And, in external marking of consumer products, the HAZ can appear as charring or discoloration compromising the value of the final device. In addition, photothermal scribing, drilling and cutting often produce an edge burr consisting of recast debris, which may require post-process removal.

Keywords :

- Ultrafast Micromachining.

- Cold Ablation.

- Semiconductor Processing.

- Glass Cutting.

- Surface Texturing.

- Medical Implants.

Ultrafast Fiber Lasers for precision micromachining of parts in semiconductor, automotive and medical industry.

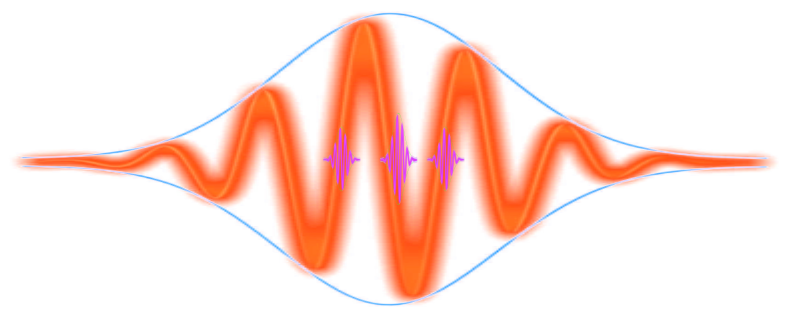

In an open paper whose free distribution may help many ultrafast-laser machining outfit to improve its manufacturing process, scientists from Beijing Institute of Technology (Beijing, China), the University of Minnesota (Minneapolis, MN), and the University of Nebraska-Lincoln have summarized their research showing how shaping femtosecond laser pulses can improve the quality of the microfabrication process. Specifically, they show that the technique improves “fabrication precision, quality, throughput, and repeatability and effectively control micro/nanoscale structures".

Keywords :

- Ultrafast Pulses .

- Temporal & Spatial shaping.

- Microfabrication.

- Micromachining.