Overview

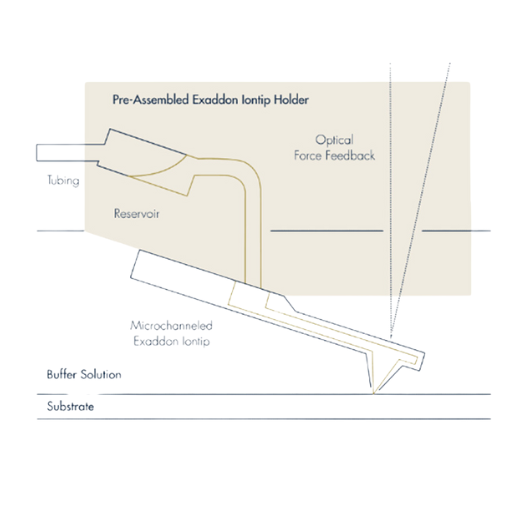

1.A small printing nozzle, called an iontip , is immersed in a supporting electrolyte bath.

2.A precisely regulated air-pressure pushes a liquid containing metal ions through a microchannel inside the iontip. The liquid flow is very small – as low as femtoliters per second.

3.At the end of the microchannel, the ion containing liquid is released onto the print surface. The print surface must be conductive; we use materials such as Cu, Au, PEDOT, and ITO.

4.The dissolved metal ions are then electrodeposited into solid metal atoms.