Applications Notes / Bulletins

Trokut Solutions caters to widest range of applications in the field of Scientific Research and Industry

Browse Direct Energy Deposition Technical Bulletins

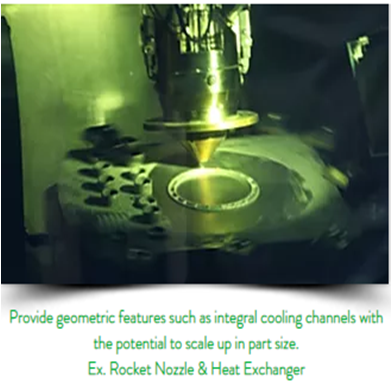

DED process can produce full parts with dimensions from less than 1 mm to greater than 1 meter with track widths from 0.5 – 8 mm and track thicknesses from 0.1 – 2.5 mm.

The FormAlloy's X & L-Series system reduce machining time and nearly eliminate material waste, particularly with high-value materials such as titanium, Inconels and others .

It can provide design features that can’t be achieved with conventional manufacturing methods, such as internal cooling channels and multi-metal parts.

Formalloy systems can deposit high-quality components with 90%+ powder efficiency and rapid speeds up to 15 lbs/hr.

Keywords :

- DED.

- Complex geometry parts printing.

- Aerospace.

- Tooling,conformal cooling.

- Medical grade materials & parts.

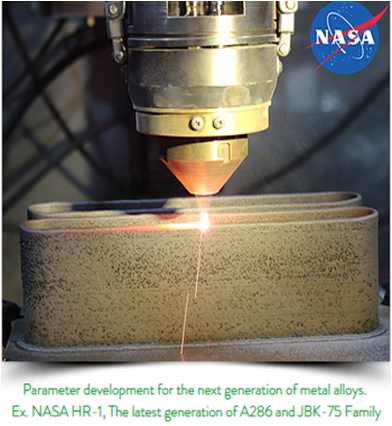

DED systems can create the most comprehensive multi material parts such as bi-metallic/gradient materials, nickel super alloys to copper alloys, titanium and magnetics .

FormAlloy's system along with Powder Feeder enables precise metering of the powder delivered to the FormAlloy AX head.

The novel planetary-drive design enables precise metering of the powder from 1 gram per minute to more than 160 grams per minute.

The modular design enables virtually unlimited configurations including multi-feeder setups for ease of powder changing and system redundancy.

The easy-align design makes powder changing possible within 5 minutes With the help of powder feeder options available customer can print multi material parts as required.

Keywords :

- Powder feeders.

- Bi-Tri metallic.

- Multi materials.

- Alloys.

- AX Deposition head.

Alloy Development feeder (ADF) allows for the precise deposition of gradient materials through pre-alloyed layers. This guarantees composition accuracy and enhanced material properties for detailed gradient parts.

FormAlloy’s ADF enables the rapid deposition of up to 16 different alloys or alloy blends. Utilizing a revolver-style motion, each powder vial can be accessed and deposited quickly and efficiently to reduce alloy development time by orders of magnitude.

The ADF is compatible with the standard FormAlloy PF feeder and can be used in parallel with multiple ADF's or PF feeders to enable interchangeability and seamless integration with the X-Series or L-Series systems.

ADF produces new alloys optimized for additive manufacturing from researchers, material companies and end users in the aerospace and automotive industries.

Keywords :

- Alloy development.

- Alloy Development Feeders. (ADF)

- Integration of PF and ADF.